My wife was hemming some thick, lined jeans with our Janome HD 3000 when suddenly the bottom thread stopped getting picked up. She re-threaded, changed the needle, to no avail. A few reddit posts later, it became apparent that a likely culprit was the hook timing. I did not know what a hook was a few hours ago, and now I have fixed it. So I wanted to write it down for others who might have this problem (including possibly my future self). I had the service manual but its instructions did not match my experience completely, and it is not very well illustrated, and I couldn’t easily find a blog post or video that was Janome-specific for hook timing.

I’m a lawyer, not a sewing machine tech, so: YMMV; these instructions are “as is no warranty”, and you open your machine and do this at your own risk.

Before you begin I’d take a look at this YouTube video, which shows a properly functioning Janome machine and gives you a general concept of the hook mechanism.

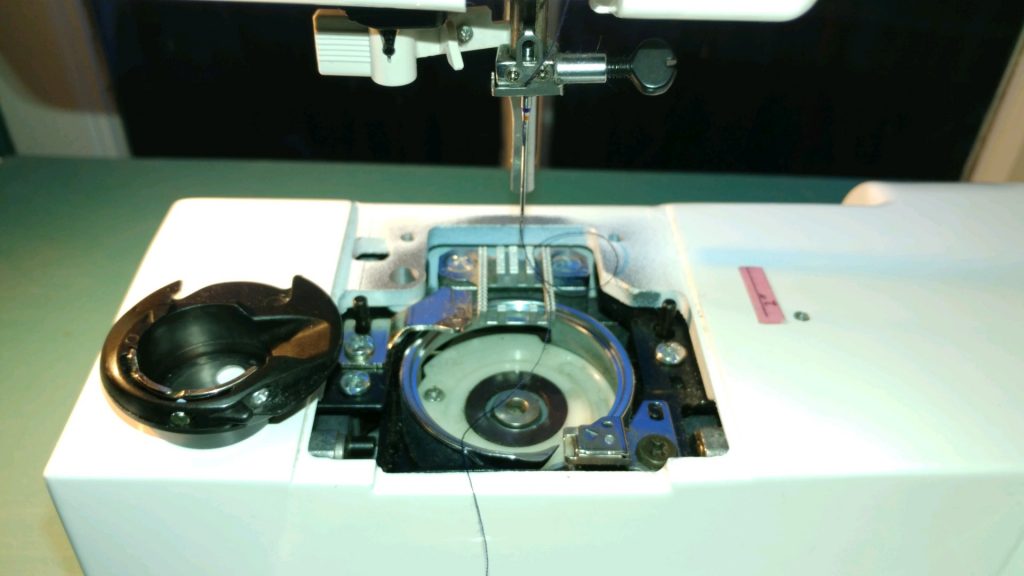

Read more: Janome HD 3000 Hook Timing Fix (Won’t Pick Up Bobbin Thread)(1) Unplug the machine. Take off the foot (single thumb screw in up position). Take off the top needle plate (one flathead screw).

(2) Take out the bobbin holder.

(3) At this point you have the view from the YouTube video above. Now would be a good time to verify that your problem is, in fact, that the hook is not picking up the thread from the needle. The video is worth 1000 words, but if you manually crank the machine with thread in the needle, holding the thread up and just behind the needle, the hook should grab it. If it misses, then proceed to step (4). Mine was missing by at least a quarter rotation, and the needle was also nicking the white plastic bottom of the bobbin-holder-well.

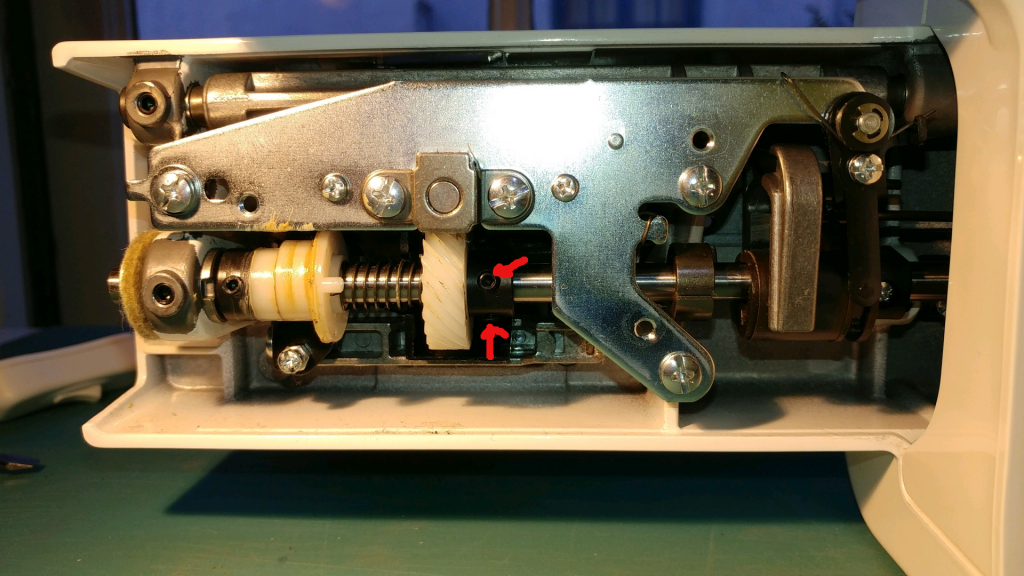

(4) You are now proceeding to detach the upper needle mechanism from the hook mechanism. Roll the machine on its back and take off the bottom plate (two screws), so you have the view below. Unscrew the two set screws marked in red, which are 2mm hex / Allen. They are really tightly screwed in. The folding allen wrenches I had at hand seemed like they would break before they budged it, so I went and got an L-shaped wrench.

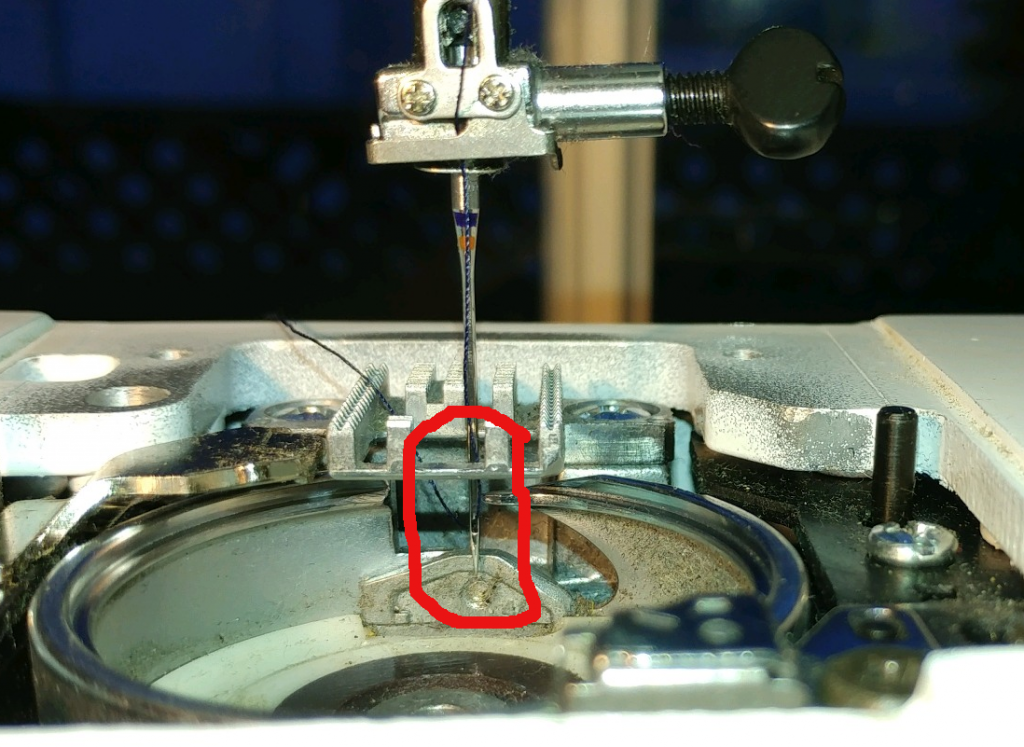

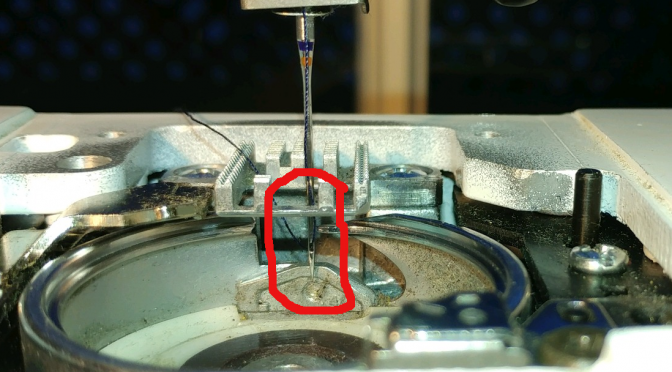

(4) The service manual at this point says to “move the needle bar 3.15 to 3.45 mm from its lowest position”. I have no idea how to measure that in the well of the bobbin holder, but I tried my best to guess. It should be on its way down, not on the way up. The manual also says to “turn the upper shaft” to move the rotary hook. Based on the manual’s picture the “upper shaft” seems to be under the metal plate of the last picture. So instead I just held the balance wheel (the “manual crank”) while holding and/or moving the rotary hook to put it in the right position. The goal is this:

You can also see basically this shot at 1:48 in the Abi’s Sewing Den video. Once you think you have that, provisionally tighten the set screws underneath, and then try hand-cranking (again: holding the thread up and back as you do so) to see if the thread gets picked up. The needle also should not contact the bottom of the bobbin holder well — you can see how it is gradated to be lower where the needle comes down. If it’s right, then tighten up the set screws hard and try sewing. If it’s not working, undo the set screws and try try again. That’s it.

Leave a Reply